- 採用耐水解、耐磨耗的TPU材質

- 可安裝於封閉型溝槽

- 有效地阻止粉塵、碎屑進入、防止液壓外漏流失

- 避免耐磨環刮傷並維持密封件的長效功

應用範圍

- 溫度: -10℃ ~ 110℃

- 速度: ≦ 1.0 m/s

- 流體: 液壓

- 材質: 聚胺脂

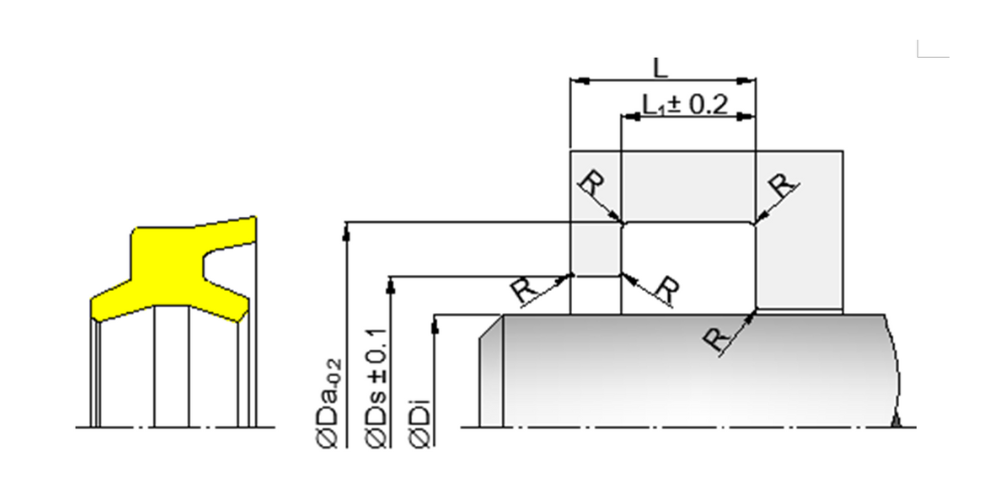

特殊尺寸選擇指南

單位:毫米| ⌀Di | ⌀Da | ⌀Ds | L | L1 |

| 14 | 22 | 18.3 | 7 | 5 |

| 16 | 24 | 20.3 | 7 | 5 |

| 18 | 26 | 22.3 | 7 | 5 |

| 20 | 28 | 24.3 | 7 | 5 |

| 22 | 30 | 26.3 | 7 | 5 |

| 24 | 32 | 28.3 | 7 | 5 |

| 26 | 34 | 30.3 | 7 | 5 |

| 28 | 36 | 32.3 | 7 | 5 |

| 30 | 38 | 34 | 8 | 6 |

| 32 | 40 | 36 | 8 | 6 |

| 34 | 42 | 38 | 8 | 6 |

| 36 | 44 | 40 | 8 | 6 |

| 38 | 46 | 42 | 8 | 6 |

| 40 | 48 | 44 | 8 | 6 |

| 42 | 50 | 46 | 8 | 6 |

| 44 | 52 | 48 | 8 | 6 |

| 46 | 54 | 50 | 8 | 6 |

| 48 | 56 | 52 | 8 | 6 |

| 50 | 58 | 54 | 8 | 6 |

| 52 | 60 | 56 | 8 | 6 |

| 54 | 62 | 58 | 8 | 6 |

| 56 | 64 | 60 | 8 | 6 |

| 58 | 66 | 62 | 8 | 6 |

| 60 | 68 | 64 | 8 | 6 |

| 62 | 70 | 66 | 8 | 6 |

| 64 | 72 | 68 | 8 | 6 |

| 66 | 74 | 70 | 8 | 6 |

| 68 | 78 | 73 | 10 | 7 |

| 70 | 80 | 75 | 10 | 7 |

| 72 | 82 | 77 | 10 | 7 |

| 74 | 84 | 79 | 10 | 7 |

| 76 | 86 | 81 | 10 | 7 |

| 78 | 88 | 83 | 10 | 7 |

| 80 | 90 | 85 | 10 | 7 |

| 82 | 92 | 87 | 10 | 7 |

| 84 | 94 | 89 | 10 | 7 |

| 86 | 96 | 91 | 10 | 7 |

| 88 | 98 | 93 | 10 | 7 |

| 90 | 100 | 95 | 10 | 7 |

| 92 | 102 | 97 | 10 | 7 |

| 94 | 104 | 99 | 10 | 7 |

| 96 | 106 | 101 | 10 | 7 |

| 98 | 108 | 103 | 10 | 7 |

| 100 | 110 | 105 | 10 | 7 |

| 102 | 112 | 107 | 10 | 7 |

| 104 | 114 | 109 | 10 | 7 |

| 106 | 116 | 111 | 10 | 7 |

| 108 | 118 | 113 | 10 | 7 |

| 110 | 120 | 115 | 10 | 7 |

| 112 | 122 | 117 | 10 | 7 |

| 114 | 124 | 119 | 10 | 7 |

| 116 | 126 | 121 | 10 | 7 |

| 118 | 128 | 123 | 10 | 7 |

| 120 | 133 | 127 | 11 | 8 |

| 122 | 135 | 129 | 11 | 8 |

| 124 | 137 | 131 | 11 | 8 |

| 126 | 139 | 133 | 11 | 8 |

| 128 | 141 | 135 | 11 | 8 |

| 130 | 143 | 137 | 17 | 12 |

| 132 | 145 | 139 | 11 | 8 |

| 134 | 147 | 141 | 11 | 8 |

| 136 | 149 | 143 | 11 | 8 |

| 138 | 151 | 145 | 11 | 8 |

| 140 | 153 | 147 | 11 | 8 |

| 142 | 155 | 149 | 11 | 8 |

| 144 | 157 | 151 | 11 | 8 |

| 146 | 159 | 153 | 11 | 8 |

| 148 | 161 | 155 | 11 | 8 |

| 150 | 163 | 157 | 11 | 8 |

| 155 | 168 | 162 | 11 | 8 |

| 160 | 173 | 167 | 11 | 8 |

| 165 | 178 | 172 | 11 | 8 |

| 170 | 183 | 177 | 11 | 8 |

| 175 | 188 | 182 | 11 | 8 |

| 180 | 193 | 187 | 11 | 8 |

| 185 | 198 | 192 | 11 | 8 |

| 190 | 203 | 197 | 11 | 8 |

| 195 | 208 | 202 | 11 | 8 |

| 200 | 213 | 207 | 11 | 8 |

| 205 | 218 | 212 | 11 | 8 |

| 210 | 223 | 217 | 11 | 8 |

| 215 | 228 | 222 | 11 | 8 |

| 220 | 233 | 227 | 11 | 8 |

| 225 | 241 | 232 | 15 | 11 |

| 230 | 246 | 237 | 15 | 11 |

| 235 | 251 | 242 | 15 | 11 |

| 240 | 256 | 247 | 15 | 11 |

| 245 | 261 | 252 | 15 | 11 |

| 250 | 266 | 257 | 15 | 11 |

| O Ring Code | Compound | Parjet Compound | Hardness (Shore A) | Temperature Range |

| 1 | NBR | N100A-70 | 70 ± 5 | -40°C ~ 100°C |

| 2 | Viton | V100A-75 | 75 ± 5 | -25°C ~ 250°C |

| 3 | NBR | N100A-90 | 90 ± 5 | -30°C ~ 100°C |

| 4 | Viton | V100A-90 | 90 ± 5 | -25°C ~ 250°C |

| 5 | NBR | N100A-80 | 80 ± 5 | -30°C ~ 100°C |

| 6 | NBR | N134A-70 | 70 ± 5 | -40°C ~ 100°C |

| 7 | EPDM | E100A-70 | 70 ± 5 | -40°C ~ 100°C |

| 8 | Silicone | S100A-70 | 70 ± 5 | -55°C ~ 210°C |

| 9 | HPU | P100A-93 | 93 ± 5 | -40°C ~ 110°C |