HiPerSeal®, aka Spring Energized Seal and Teflon Spring Seal, is a U-shaped machined performance polymer that utilizes a single spring energizer to provide force for the sealing lips. The seal jacket is made from PTFE compounds using high-performance polymer fillers to enhance overall spring seal life and wear resistance properties. The system pressure ultimately increases the sealing force and creates a leak tight seal. Because the spring loaded seal utilizes a spring, slight misalignment is tolerated, and the sealing force and jacket wear is more consistent. Spring energizers are available in corrosion resistant metal alloys such as stainless steel, Elgiloy and Hastelloy to meet the most serious corrosive and high temperature applications. We offer a wide variety of springs energizers including Canted Coil springs, Helical springs and Cantilever springs. For more information, you may refer to the tab "Spring" under "Products".

The standard spring seal product line is precisely machined to fit AS 568A glands in radial rod and piston grooves and axial face seal configurations. They are suitable for static, rotary, and reciprocating applications which can operate under the most extreme and harsh conditions. They can operate from static and low speeds to speeds of 20 m/s (4000 fpm); pressures from vacuum to 700 kg/cm² (10,000 psi); and temperatures from cryogenic to 300°C (575°F). The spring loaded seal series offers all these capabilities while being able to function in the most chemically aggressive applications. These seals are an extremely effective solution for hydraulic components where low friction and high lateral loads, are combined with corrosive and/or steam environments; all while providing the most consistent friction performance.

HiPerSeal® can of course be customized to meet your specific needs upon request.

Advantage of HiPerSeal®:

• Manufactured with dedicated CNC machines, there are no tooling costs. Ideal for small quantities and diverse customized requirements.

• Versatile sealing spring loads through various spring and seal profile designs.

• A compact spring seal that will fit in standard O-ring grooves in accordance with AS568A.

• Sterilize in autoclaves or with any sterilizing agents.

HiPerLip®, also known as PTFE Shaft Seal, is a rotary shaft seal with a PTFE sealing lip and metal casing. The rotary seal is ideal for sealing high-speed rotary applications with very low friction and minimal power draw to achieve better performance, higher response, and precision. Thanks to excellent PTFE compounds and the unique sealing lip construction, the PTFE rotary lip seal with metal case provides superior performance over conventional rotary oil seals, especially in high rotary, poorly lubricated, highly corrosive, high temperatures, and other extreme working environments. Typical temperatures range from -60°C to 200°C (-76°F to 390°F), and shaft speeds up to 30 m/s (5,905 fpm) for low pressure applications.

The radial contact pressure of the HiPerLip® sealing lip produces leak tight sealing action on the shaft. This is achieved by a combination of correct PTFE seal lip geometry, static seal (gasket), precise steel casing and forming process. For special sizes or high corrosion environment, 100% PTFE can be used without any steel casing. The interference is compliant with that specified in DIN 3760, ensures static sealing between steel casing of HiperLip® and the seal housing. Our standard steel casing material is mild steel (SPCD) but other materials like stainless steel (JIS SUS 304, DIN 1.4301) are available upon request.

For leak critical applications, a threaded PTFE sealing lip (a spiral groove machined into the seal lip) on the medium side, can provide a hydrodynamic pumping effect.

Advantages:

• Suitable for high speed and low to medium pressure applications.

• Very low break-out and dynamic friction even after long down-times.

• Excellent service life due to abrasive resistant lip compounds.

• Suitable for short-term dry running and long-term poorly lubricated conditions.

• Nearly versatile chemical resistance (depending on rotary seal lip and steel casing material choice).

HiPerFlon® is a rotary lip seal that features an ID lip that seals dynamically on shaft and with O-ring centered on the OD. They are suitable for medium to high speed with low pressure application. It is widely chosen when the rotary speeds exceed the capabilities of elastomeric seals.

With the unique sealing lip construction and excellent self-lubricated features of PTFE compounds, the PTFE rotary lip seal provides superior performance over conventional rubber oil seals. Typical speeds for HiPerFlon® seals are 25 m/s (4925 fpm) and above.

PTFE rotary shaft seals are available in a wide variety of PTFE compounds, and utilize common O-ring material choices like fluorocarbon, silicone, nitrile, and EPDM. The use of standard O-ring and PTFE compounds create an easily adaptable solution for all kinds of high-speed applications.

Standard HiPerFlon® sizes are precision machined to fit inch-fractional and metric gland geometries, and in-house processing allows custom seal cross sections and diameters to meet any customer request.

PTFE Glide seal sets consists of a PTFE sealing element with a rubber O-ring functioning as elastic energizer. This type of Teflon seal is mainly used to seal reciprocating rods, pistons, and plungers, commonly found in hydraulic and pneumatic applications. The required sealing effect is achieved by radial pressure, produced by the preloaded element and system pressure, on the lip against mating surface. The elastic energizer pushes the PTFE ring against the mating surface which provides the initial sealing force for the PTFE seal.

PTFE Glide seal sets can provide much lower friction without any stick-slip effect to guarantee smooth running even for intermittent operation or long-stroke application. They perform reliable sealing even under high service pressures and surface speeds. The inherent low friction and wear resistant properties of our PTFE compounds will effectively improve the service life of the seals and help reduce maintenance costs. PTFE seal sets are also preferred for applications with difficult operating conditions such as construction equipment, chemical processing, off-shore, galvanizing and color coating lines, and coal-fired power plants where dusty, high temperature, aggressive media, or intermittent motion are quite common. They are also widely used in food, medical and semiconductor processing equipment as well.

Various seal profiles can fit most single and double acting cylinders. Some compact profiles have been well developed to fit AS 568A standard O-ring grooves for one or two back-up rings.

PTFE Seal Advantages:

• Excellent gliding characteristics due to low friction of the PTFE compounds.

• Wear resistance can be improved by proprietary fillers.

• Very good sealing most chemicals.

• High extrusion resistance.

• Good thermal conductivity.

• Full range of sizes available.

• Easy fitting.

PTFE Seal Applications:

• Low break-out and low friction hydraulic cylinders.

• Low friction and no stick-slip pneumatic cylinders.

• Plungers.

• Cylinders in corrosive environments.

• Low friction cylinders in high-temperature applications.

• Cylinders for machine tools and construction equipment.

• Cylinders for Press/Extrusion/Injection molding equipment.

• Cylinders for precision control applications.

Parjet provides whole series of hydraulic seals meeting the requirements of harsh operating conditions such as steel industry, construction machinery, off-shore facilities, transmission & storage, and tire industries. For those applications involving JIS, ISO, ANSI/NFPA international standard sealing grooves, Parjet can provide instant sealing solution.

Our hydraulic rubber seals are designed to withstand demanding hydraulic conditions, ensuring reliable sealing and optimal system efficiency.

We offer a wide range of hydraulic rubber seals to meet diverse industry needs. Our hydraulic sealing solution includes:

• Piston Seals: Engineered to fit tightly around the piston rod or cylinder bore, piston seals prevent fluid leakage during reciprocating motion, ensuring efficient cylinder performance.

• Rod Seals: Designed to seal the reciprocating motion of hydraulic cylinder rods, rod seals prevent leakage of hydraulic fluid and protect the system from contaminants.

• Wiper Seals: These seals, also known as scraper seals, clean contaminants such as dirt and moisture from hydraulic cylinder rods during retraction, prolonging the lifespan of other seals and components.

Parjet’s hydraulic rubber seals are made in a variety of materials to suit different application requirements. Some commonly used materials include:

1. Nitrile (NBR)

2. Fluorocarbon (FKM/Viton®)

3. Polyurethane (PU)

4. PTFE (*For PTFE Hydraulic Seals, please refer to “PTFE Glide Seal Set” under “Products”)

We understand that each hydraulic application is unique, with specific requirements and operating conditions. As a result, our engineering team uses advanced & world-known CNC precision lathes to design and manufacture the hydraulic seals tailored to your application, ensuring optimal performance and sealing efficiency.

With our extensive experience, commitment to quality, and advanced manufacturing capabilities, we are the trusted partner for all your hydraulic sealing solutions.

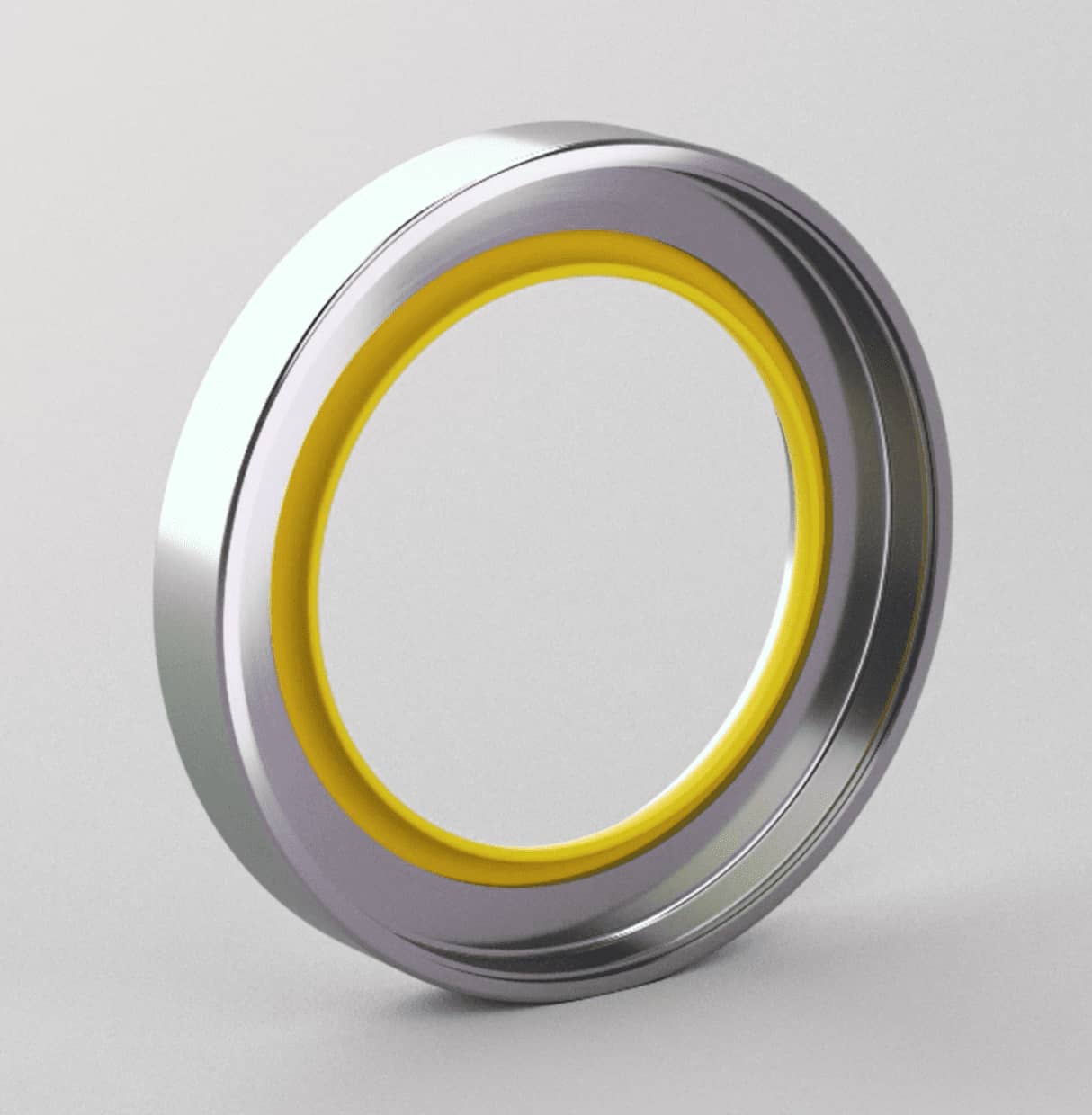

ParSave® - Bearing Isolator, is an extension of Parjet PTFE products. It is a sealing device developed to protect the rolling bearings of rotary equipment and can replace traditional lip seals (also known as rubber oil seals). The special configuration of the labyrinth ring combination helps to eliminate common sealing issues. Common issues includes the shaft damages caused by the wear of the rotating shaft from the lip seals and malfunction caused by the intrusion of foreign objects or water vapor. ParSave® can effectively extend the service life of the bearings and rotating shafts. Additionally, due to the unique sealing mechanism, there is no contact between mating surfaces, so there are no potential wear and pollution problems. With the characteristics of the PTFE material such as excellent heat resistance, self lubrication and chemical resistance, ParSave® can operate effectively under harsh environments.

Features of ParSave Bearing Isolators:

The ParSave bearing isolator is evolved from the design concepts of major foreign leading brands and uses the characteristics of materials to enhance the dynamic and static rings perform a fitting precision combination. The static O-ring seal completely blocks out the leaking path of the inner bore. ParSave's powerful oil splashing labyrinth groove and lubricating oil mechanism design ensure the quality of lubricating oil. In addition to providing the braking force that synchronous rotates with the shaft, the centrifugal force provided by O-ring during rotation and the internal labyrinth will effectively remove and discharge the high-humidity pollutants to achieve a double-layer protection effect.

The ParSave series bearing isolator adopts a simple and integrated design without any special tools to install. It is the best choice for you to reduce maintenance costs and improve the reliability of the equipment operation.

Applications of ParSave Bearing Isolators:

ParSave® is suitable for cooling water towers, wastewater treatment or non-pressure acid and alkali treatment equipment. It is completely free of corrosion problems therefore suitable to be used in extreme operating conditions, for instance the gearboxes with a long-term high humidity, dust, and water vapor splash environment. ParSave® can replace the traditional lip seal and offer an effective isolation protection for the bearings and lubricating oil. This significantly reduces the probability of water intrusion and extend the service life of the bearing.

Our Parjet ParSave® engineering team has rich experience and capabilities in design, production, application, and diagnosis of problems. We provide optimal designs and selections for the shaft seal requirements of any rotary equipment such as motors, pumps, fans, mixers, compressors, etc. We can meet the customers’ needs in a short lead time even with customized designs.

• It can ensure that the lubricating grease is not polluted and prolong the operating life of the bearing

• The surface of the shaft will not be worn; reducing maintenance costs

• No interference phenomenon during operation, no increase in torque & power

• Seal Mechanism design performs an isolation effect

• The properties of the applied materials are not impacted by chemical substances

• The most lightweight and simple design

Parjet has become a leader in the sealing industry by providing a full range of sealing solutions. For every complex seal application, Parjet has a solution.

Mechanical shaft seals are often an ideal sealing method. They provide the most suitable sealing method under many conditions especially high temperatures, high pressures, high viscosity (sediment), high speeds, large diameters, and many others. Most importantly, we have a highly technical mechanical seal providing and customizing the most optimal sealing solution for you.

Parjet has developed a series of mechanical seals and related products that are applied in chemical, oil refining, biotechnology, power plant, aerospace, and other industries. Combing the professional advanced techniques from around the world, our team provides diagnosis and consultation for various sealing problems. We look forward to offering the best sealing solutions for your application.

Parjet has worked with Springs for over 30 years of experiences in the sealing industry. We manufacture and offer various types of springs, from Cantilever springs that are mostly used for spring energized seals to Helical Spring that can be used in both spring energized seals and EMI shielding purposes. We also provide Canted Coil Springs that can perform EMI shielding, electricity conductivity and mechanical fastening purposes. These springs has been widely used in various industries including aerospace, transportation, oil & gas, offshoring, medical and construction industry.

• Cantilever Spring:

Cantilever springs, also known as V spring, is a V shaped pattern design spring. It is commonly used for spring energizing purposes. The geometry of the cantilever spring allows it to have a linear load - deflection curve and can be used in both slow to moderate dynamics and static sealing applications. It is the preferred choice for reciprocating sealing applications. Our Cantilever spring can be customized with different materials, sizes and length.

• Helical Spring:

Helical Spring, also known as spiral spring, has a round cross section, it is the composition of wounded flat ribbon metal. Helical Spring has a high load with smaller deflection range. The design of the helical spring allows the load to distribute evenly across each individual band. It is commonly used in spring energized seals, EMI shielding and electricity conductivity purposes. For spring energizing purposes, it is commonly used in medium to high pressure applications under static or very low speed motion. It is the preferred choice for seal radial and face sealing. Our Helical spring can be customized with different materials, sizes, dimensions, length and plating.

• Canted Coil Spring:

Canted Coil Spring, also known as Slanted Coil Spring, has a unique oval cross section design. The geometry of Canted Coil Spring allows it to have a flat load curve in a certain deflection range. Based on the designed dimensions, the spring load can be customized. Canted Coil spring is typically used in dynamic with light to medium pressure motion and are suitable under wide tolerance and glands. Apart from spring energized seals, Canted Coil Spring can also be used by itself for EMI shielding, electricity conductivity and mechanical connecting purposes, such as locking, latching and holding. Our Canted Coil Spring can be customized with different materials, sizes, dimensions, length and plating.

In case you have any inquires on the Cantilever Spring, Helical Spring and Canted Coil Spring, please do not hesitate to contact us.

PTFE Bushes, also known as line bearings, are used in applications where standard metal material bush cannot be used in the extreme environment such as abrasive environment. With our professional engineering team, we design and manufacture PTFE Bushes in-house. Due to wide range of applications, every client will have different operating conditions, therefore the flexibility to adapt to different environment is key. Parjet can customize based on the client's needs in a short lead time.

The advantages of PTFE bushes includes:

- Low coefficient of friction

- Light weight

- High chemical resistance

- High temperature resistance

- Applicable for softer shaft

- Meet with RoHS Standards

- Self-lubrication characteristics

- Easy to machine and customize

We offer the following materials for the PTFE bushes:

1. 01R – Equivalent to Rulon® 1337 FDA

2. 02R - Equivalent to Rulon® 641 FDA

3. 03R – Equivalent to Rulon® J

4. 04R – Equivalent to Rulon® LR

Contact us for more information on PTFE molded Bushes. Our engineering team will be happy to help with your application.

Parjet provides PTFE customized products, including PTFE balls which can be customized into different sizes and materials. Contact us for more information.

MORE

Wear Ring, also known as guide tapes, wear tapes, guide ring, are widely used in hydraulic cylinders. They are mainly used for keeping the piston centered and absorbing radical pressures and wear that are perpendicularly distributed along the cylinder.

This component is used to machines to reduces the friction and wear between the moving parts, for instance, the stationary casing or housing. Wear rings play a crucial role in improving the efficiency, reliability and lifespan of different hydraulic equipment.

Parjet's standard material for wear rings is PTFE + Bronze but other PTFE materials are avaliable upon request. Please contact us for more information.

O-rings are crucial components widely utilized in sealing technology. Common rubber O-rings, such as those made of NBR (Nitrile Butadiene Rubber), are frequently employed in hydraulic and pneumatic systems.

When selecting the material for O-rings, it is essential to consider factors such as pressure, temperature, and chemical corrosiveness in the application environment. Choosing the appropriate material for O-rings ensures sealing performance, extends lifespan, and enhances equipment reliability.

Parjet provides O-rings with different characteristics tailored to various application environments. It's our mission to provide suitable O-ring materials based on specific application requirements.

Common O-rings materials include:

Nitrile Butadiene Rubber (NBR)

Hydrogenated Nitrile Butadiene Rubber (HNBR)

Fluorocarbon Rubber (Viton)

Ethylene Propylene Diene Monomer (EPDM)

Silicone Rubber (VMQ)

Chloroprene Rubber (CR)

Fluorosilicone Rubber (MFQ)

Polyurethane (PU)

If you have any further questions such as hardness levels or temperatures, feel free to contact our engineering team.