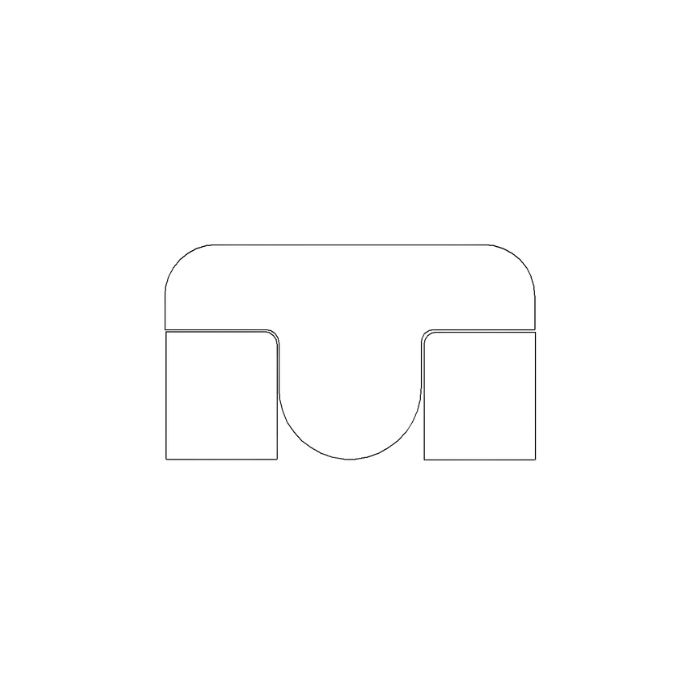

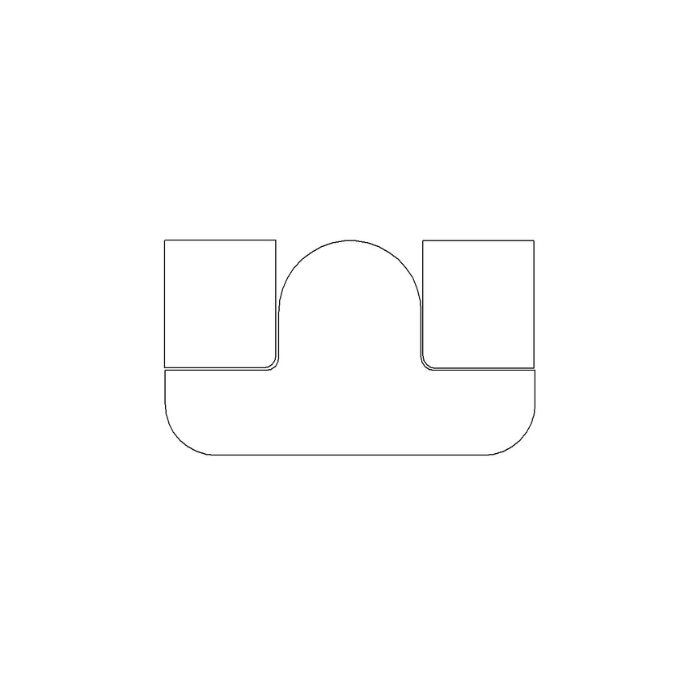

PTFE Glide seal sets consists of a PTFE sealing element with a rubber O-ring functioning as elastic energizer. This type of Teflon seal is mainly used to seal reciprocating rods, pistons, and plungers, commonly found in hydraulic and pneumatic applications. The required sealing effect is achieved by radial pressure, produced by the preloaded element and system pressure, on the lip against mating surface. The elastic energizer pushes the PTFE ring against the mating surface which provides the initial sealing force for the PTFE seal.

PTFE Glide seal sets can provide much lower friction without any stick-slip effect to guarantee smooth running even for intermittent operation or long-stroke application. They perform reliable sealing even under high service pressures and surface speeds. The inherent low friction and wear resistant properties of our PTFE compounds will effectively improve the service life of the seals and help reduce maintenance costs. PTFE seal sets are also preferred for applications with difficult operating conditions such as construction equipment, chemical processing, off-shore, galvanizing and color coating lines, and coal-fired power plants where dusty, high temperature, aggressive media, or intermittent motion are quite common. They are also widely used in food, medical and semiconductor processing equipment as well.

Various seal profiles can fit most single and double acting cylinders. Some compact profiles have been well developed to fit AS 568A standard O-ring grooves for one or two back-up rings.

PTFE Seal Advantages:

• Excellent gliding characteristics due to low friction of the PTFE compounds.

• Wear resistance can be improved by proprietary fillers.

• Very good sealing most chemicals.

• High extrusion resistance.

• Good thermal conductivity.

• Full range of sizes available.

• Easy fitting.

PTFE Seal Applications:

• Low break-out and low friction hydraulic cylinders.

• Low friction and no stick-slip pneumatic cylinders.

• Plungers.

• Cylinders in corrosive environments.

• Low friction cylinders in high-temperature applications.

• Cylinders for machine tools and construction equipment.

• Cylinders for Press/Extrusion/Injection molding equipment.

• Cylinders for precision control applications.