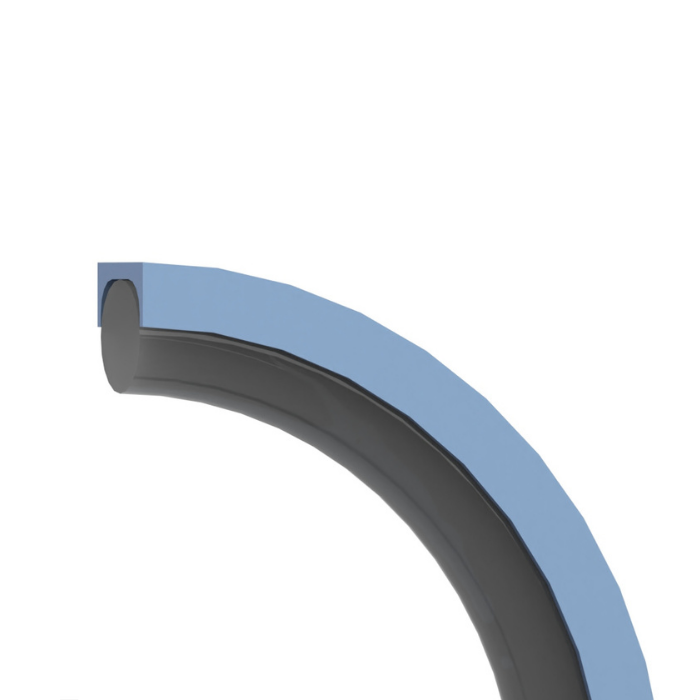

- Design to retrofit standard O-ring gland in bi-directional pressurization, hydraulic applications.

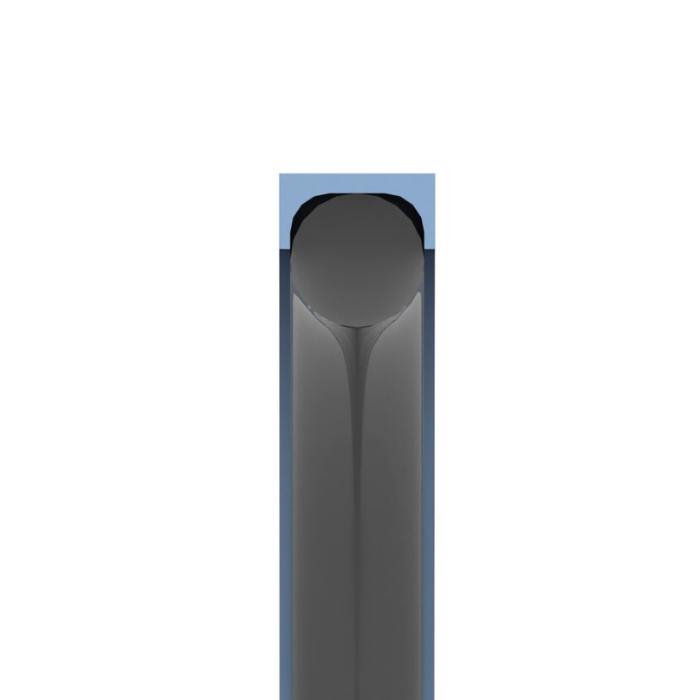

- Higher extrusion resistance

- Excellent chemical and temperature resistance

- No stick-slip movement even in low velocities

- High extrusion and temperature resistance

Application Range

- Pressure: ≦ 350 bar

- Temperature: -40℃ ~ 200℃

- Speed: ≦ 4 m/s

- Standard Material: Virgin PTFE

- (Note: Other materials are available for specified conditions)

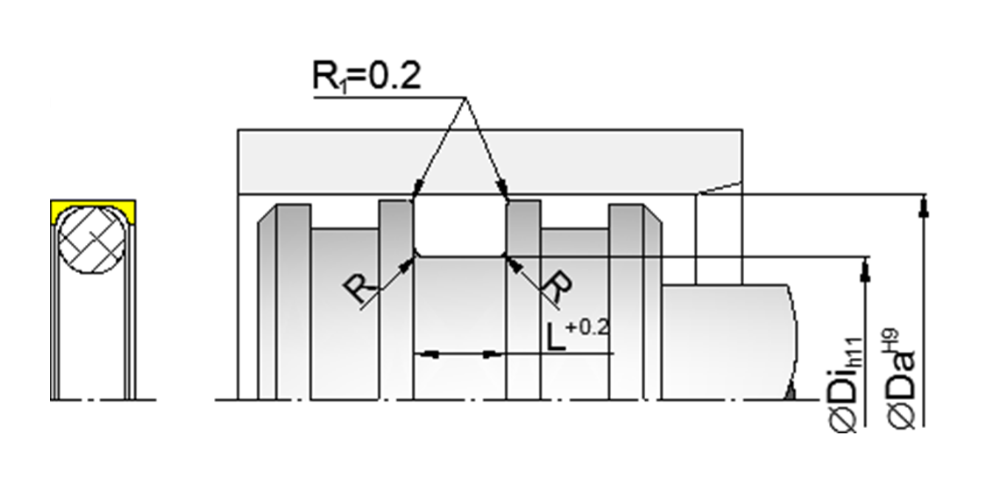

Guidelines for the Selection of Special Sizes

Unit: mm| Piston Diameter | Groove Bottom | Groove Width | Groove Width | Groove Width | Radius | Gap | Gland code | O-Ring C.S. |

| ⌀ Da | ⌀ Di | 0 backup ring | 1 backup ring | 2 backup ring | R | T | ||

| 8 ~ 13.9 | Da - 2.9 | 2.4 | 3.8 | 5.3 | 0.4 | 0.1 | A | 1.78 |

| 14 ~ 24.9 | Da - 4.5 | 3.6 | 4.65 | 6.2 | 0.4 | 0.15 | B | 2.62 |

| 25 ~ 45.9 | Da - 6.2 | 4.8 | 5.7 | 7.7 | 0.6 | 0.25 | C | 3.53 |

| 46 ~ 124.9 | Da - 9.4 | 7.1 | 8.5 | 10.8 | 0.8 | 0.35 | D | 5.33 |

| 125 ~ 669.9 | Da - 12.2 | 9.5 | 11.2 | 14.7 | 0.8 | 0.5 | E | 6.99 |

| 670 ~ 999.9 | Da - 15.0 | 11.0 | 14 | 17 | 1.0 | 0.6 | F | 8.40 |

| Material code | Reference | Compound | Color | Temp. °C (MIN.) | Temp. °C (MAX.) | Application | Characteristics | Products |

| 1 | 01T | VIRGIN PTFE | WHITE | -190 | 220 | • CHEMICAL INDUSTRY • SEMI-CONDUCTOR • FOOD INDUSTRY | • HIGH CHEMICAL RESISTANCE • LOW COEFFICIENT OF FRICTION | • BACK-UP RINGS • HIPERSEALS |

| 2 | 03T | PTFE + 23% CARBON + 2% GRAPHITE | BLACK | -190 | 315 | • HIGH MECHANICAL STRESS • WATER/OIL HYDRAULICS • ROTARY SEALING | • HIGH WEAR RESISTANCE • CREEP RESISTANCE | • GLIDE RINGS • PNEUMATIC GUIDANCE TAPE • BACK-UP RINGS • HIPERSEAL |

| 3 | 02T | PTFE + 40% BRONZE | GREEN | -156 | 260 | • HIGH MECHANICAL STRESS • HYDRAULIC APPLICATIONS | • OUTSTANDING WEAR RESISTANCE • EXTRUSION RESISTANCE • CREEP RESISTANCE | • GLIDE RINGS • HYDRAULIC GUIDANCE TAPE • BACK-UP RINGS |

| 4 | UPE | UHMW-PE | WHITE | -200 | 80 | • HYDRAULIC APPLICATIONS | • OUTSTANDING WEAR RESISTANCE • GOOD OXIDATION RESISTANCE • OUTSTANDING EXTRUSION RESISTANCE • OUTSTANDING SEALING UNDER LOW PRESSURE | • BACK-UP RINGS • SPRING ENERGIZED SEALS |

| 4G | 4G | ULTRAGOLD® | YELLOW | CRYOGENIC | 93 | • HYDRAULIC APPLICATIONS | • OUTSTANDING WEAR RESISTANCE • SELF-LUBRICATING PROPERITIES • OUTSTANDING EXTRUSION RESISTANCE • OUTSTANDING PERFORMANCE UNDER CRYOGENIC APPLICATION | • HIPERSEALS |

| 5 | 05T | PTFE + 10% CARBON FIBER | GREY | -260 | 310 | • WATER HYDRAULICS • SHORT STROKES WITH HIGH OPERATION FREQUENCY | • VERY GOOD WEAR RESISTANCE PROPERTIES IN WATER • EXCELLENT COMPRESSIVE STRENGTHS • DYNAMIC APPLICATIONS AT HIGH SPEED | • GLIDE RINGS • HIPERSEALS |

| 6 | 06T | PTFE + 25% GLASS FIBER | WHITE | -190 | 290 | • MEDIUM-DUTY HYDRAULIC APPLICATIONS | • HIGH CHEMICAL RESISTANCE • HIGH CREEP RESISTANCE • ELECTRICAL PROPERTIE LIKE VIRGIN PTFE | • GLIDE RINGS • BACK-UP RINGS • GUIDE RINGS • GASKETS |

| 7 | 07T | PTFE + 10% EKONOL | BEIGE | -260 | 320 | • MEDIUM MECHANICAL STRESS • SOFTER SEALING SURFACES • ROTARY SEALING | • LIMITED CHEMICAL RESISTANCE • LIMITED USE IN HOT WATER | • HIPERSEALS • ROTARY GLIDE RINGS • LIP SEALS |

| 8 | 08T | PTFE + E-CARBON | BLACK | -190 | 290 | • MEDIUM MECHANICAL STRESS • HARD SEALING SURFACES • WATER/OIL EMULSIONS | • CHEMICAL RESISTANCE LIMITED BY CARBON | • HIPERSEALS |

| 9 | 09T | PTFE + 15% GRAPHITE | DARK GREY | -190 | 260 | • LOW MECHANICAL STRESS • SOFT SEALING SURFACES | • CHEMICAL RESISTANCE LIMITED GRAPHITE | • HIPERSEALS |

| 10 | 10T | PTFE + 15% GLASS FIBER + 5% MOS2 | GREY | -190 | 260 | • MEDIUM MECHANICAL STRESS • MEDIUM-DUTY HYDRAULIC APPLICATIONS | • HIGH CREEP STRENTH • HIGH CHEMICAL RESISTANCE • OUTSTANDING WEAR RESISTANCE • ELECTRICAL PROPERTIES LIKE VIRGIN PTFE | • HIPERSEALS • ROTARY SEALS • BACK-UP RINGS |

| PE | 01K | PEEK | BEIGE/ BLACK | -73 | 316 | • HYDRAULIC APPLICATIONS | • GOOD CHEMICAL RESISTANCE • GOOD WEAR RESISTANCE • HIGH MAXIMUM USE TEMPERATURE • LOW FLAMMABILITY • EXCELLENT ELECTRICAL PROPERTIES • GOOD RADIATION RESISTANCE | • BACK-UP RINGS • HIPERSEALS |

| O Ring Code | Compound | Parjet Compound | Hardness (Shore A) | Temperature Range |

| 1 | NBR | N100A-70 | 70 ± 5 | -40°C ~ 100°C |

| 2 | Viton | V100A-75 | 75 ± 5 | -25°C ~ 250°C |

| 3 | NBR | N100A-90 | 90 ± 5 | -30°C ~ 100°C |

| 4 | Viton | V100A-90 | 90 ± 5 | -25°C ~ 250°C |

| 5 | NBR | N100A-80 | 80 ± 5 | -30°C ~ 100°C |

| 6 | NBR | N134A-70 | 70 ± 5 | -40°C ~ 100°C |

| 7 | EPDM | E100A-70 | 70 ± 5 | -40°C ~ 100°C |

| 8 | Silicone | S100A-70 | 70 ± 5 | -55°C ~ 210°C |

| 9 | HPU | P100A-93 | 93 ± 5 | -40°C ~ 110°C |