HiPerSeal® - Spring Energized Seal

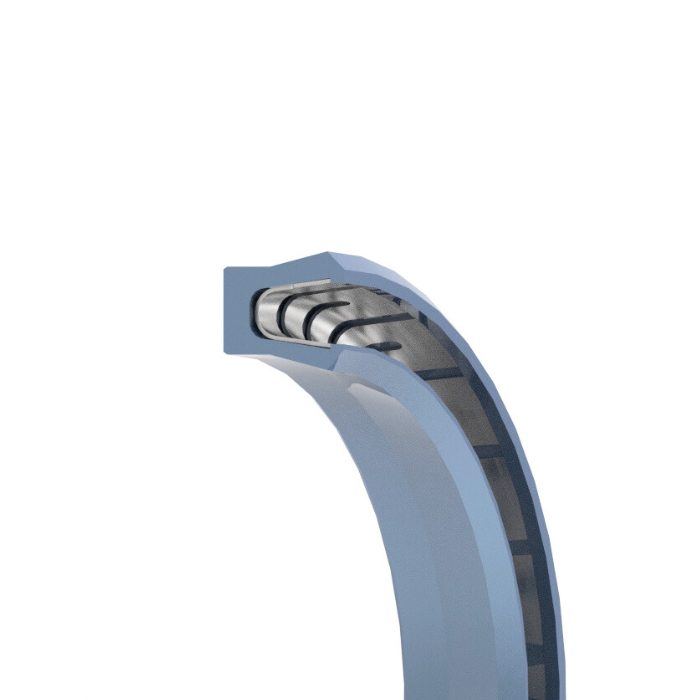

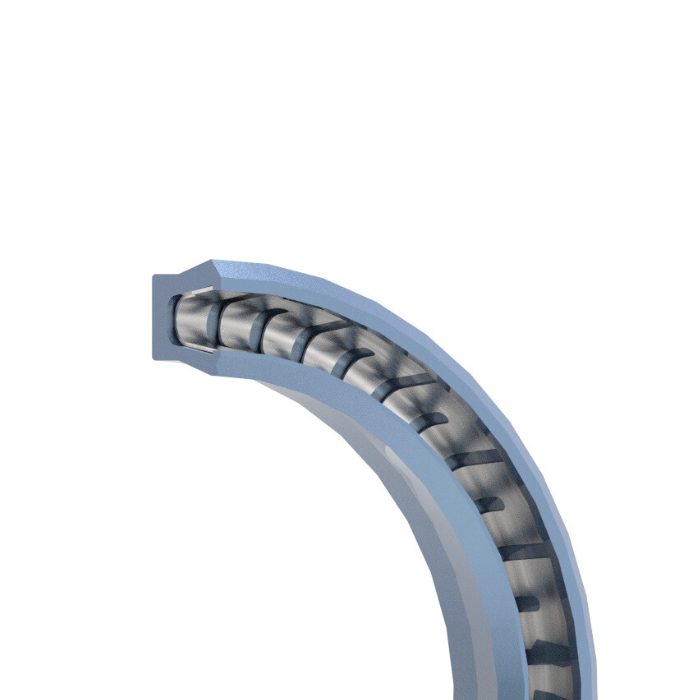

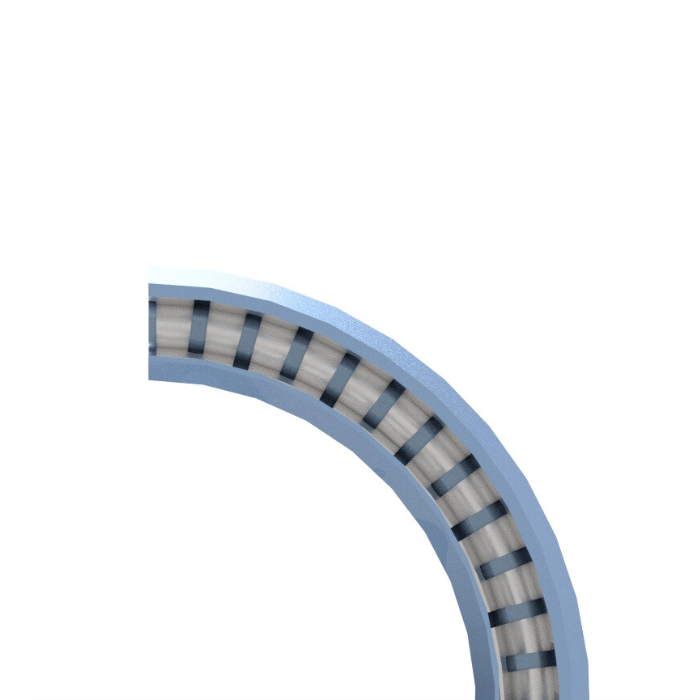

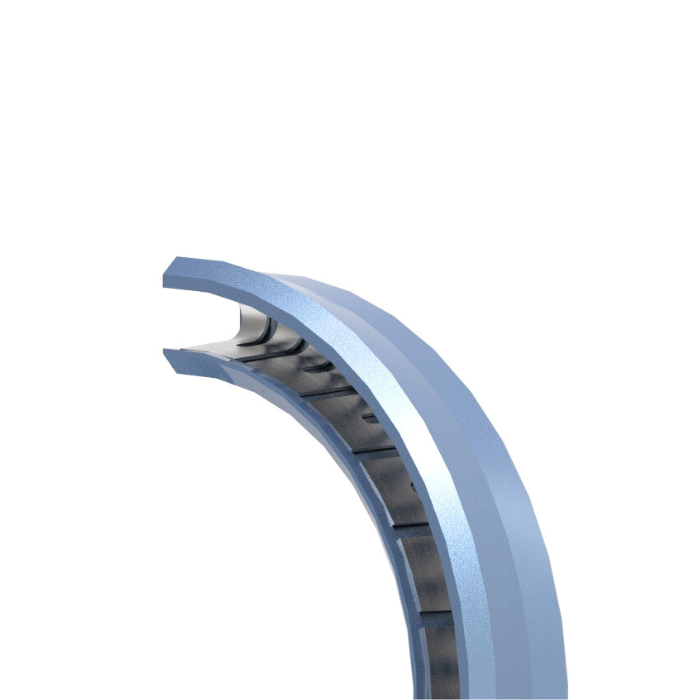

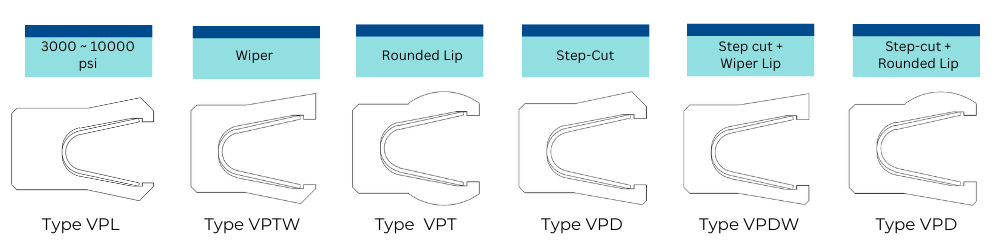

Spring Energized Seal | Type VP

Piston seal for reciprocating application with cantilever spring.

- Suitable for medium load conditions

- Counterface: below 3000 psi

- Very good sealability under low pressure

- Friction: Medium

- Standard Materials: Carbon fiber Filled PTFE material code: 5

- (Other materials are available for special operating conditions. Our application engineers will be glad to advise you.)

Application Range

- Pressure: ≤ 350 Bar

- Sliding speed: ≤ 15 m/s

- Temperature: -150°C ~ 225°C

Common Applications

Optional Design

Guidelines for the Selection of Special Sizes

Unit: mm| Piston diameter | Groove Bottom | Groove Width | Gap | Radius | Equivalent O-Ring Cord | O-Ring code |

| ⌀ Da | ⌀ Di | L | T | R | Thickness | |

| 6 ~ 13.9 | Da - 2.9 | 2.4 | 0.06 | 0.4 | 1.78 | A |

| 14 ~ 24.9 | Da - 4.5 | 3.6 | 0.06 | 0.4 | 2.62 | B |

| 25 ~ 45.9 | Da - 6.2 | 4.8 | 0.07 | 0.6 | 3.53 | C |

| 46 ~ 124.9 | Da - 9.4 | 7.1 | 0.08 | 0.8 | 5.33 | D |

| 125 ~ 700 | Da - 12.2 | 9.5 | 0.12 | 0.8 | 6.99 | E |

| Material code | Reference | Compound | Color | Temp. °C (MIN.) | Temp. °C (MAX.) | Application | Characteristics | Products |

| 1 | 01T | VIRGIN PTFE | WHITE | -190 | 220 | • CHEMICAL INDUSTRY • SEMI-CONDUCTOR • FOOD INDUSTRY | • HIGH CHEMICAL RESISTANCE • LOW COEFFICIENT OF FRICTION | • BACK-UP RINGS • HIPERSEALS |

| 2 | 03T | PTFE + CARBON + GRAPHITE | BLACK | -190 | 315 | • HIGH MECHANICAL STRESS • WATER/OIL HYDRAULICS • ROTARY SEALING | • HIGH WEAR RESISTANCE • CREEP RESISTANCE | • GLIDE RINGS • PNEUMATIC GUIDANCE TAPE • BACK-UP RINGS • HIPERSEAL |

| 3 | 02T | PTFE + BRONZE | GREEN | -156 | 260 | • HIGH MECHANICAL STRESS • HYDRAULIC APPLICATIONS | • OUTSTANDING WEAR RESISTANCE • EXTRUSION RESISTANCE • CREEP RESISTANCE | • GLIDE RINGS • HYDRAULIC GUIDANCE TAPE • BACK-UP RINGS |

| 4 | UPE | UHMW-PE | WHITE | -200 | 80 | • HYDRAULIC APPLICATIONS | • OUTSTANDING WEAR RESISTANCE • GOOD OXIDATION RESISTANCE • OUTSTANDING EXTRUSION RESISTANCE • OUTSTANDING SEALING UNDER LOW PRESSURE | • BACK-UP RINGS • SPRING ENERGIZED SEALS |

| 4G | 4G | ULTRAGOLD® | YELLOW | CRYOGENIC | 93 | • HYDRAULIC APPLICATIONS | • OUTSTANDING WEAR RESISTANCE • SELF-LUBRICATING PROPERITIES • OUTSTANDING EXTRUSION RESISTANCE • OUTSTANDING PERFORMANCE UNDER CRYOGENIC APPLICATION | • HIPERSEALS |

| 5 | 05T | PTFE + CARBON FIBER | GREY | -260 | 310 | • WATER HYDRAULICS • SHORT STROKES WITH HIGH OPERATION FREQUENCY | • VERY GOOD WEAR RESISTANCE PROPERTIES IN WATER • EXCELLENT COMPRESSIVE STRENGTHS • DYNAMIC APPLICATIONS AT HIGH SPEED | • GLIDE RINGS • HIPERSEALS |

| 6 | 06T | PTFE + GLASS FIBER | WHITE | -190 | 290 | • MEDIUM-DUTY HYDRAULIC APPLICATIONS | • HIGH CHEMICAL RESISTANCE • HIGH CREEP RESISTANCE • ELECTRICAL PROPERTIE LIKE VIRGIN PTFE | • GLIDE RINGS • BACK-UP RINGS • GUIDE RINGS • GASKETS |

| 7 | 07T | PTFE + EKONOL | BEIGE | -260 | 320 | • MEDIUM MECHANICAL STRESS • SOFTER SEALING SURFACES • ROTARY SEALING | • LIMITED CHEMICAL RESISTANCE • LIMITED USE IN HOT WATER | • HIPERSEALS • ROTARY GLIDE RINGS • LIP SEALS |

| 8 | 08T | PTFE + E-CARBON | BLACK | -190 | 290 | • MEDIUM MECHANICAL STRESS • HARD SEALING SURFACES • WATER/OIL EMULSIONS | • CHEMICAL RESISTANCE LIMITED BY CARBON | • HIPERSEALS |

| 9 | 09T | PTFE + GRAPHITE | DARK GREY | -190 | 260 | • LOW MECHANICAL STRESS • SOFT SEALING SURFACES | • CHEMICAL RESISTANCE LIMITED GRAPHITE | • HIPERSEALS |

| 10 | 10T | PTFE + GLASS FIBER + MOS2 | GREY | -190 | 260 | • MEDIUM MECHANICAL STRESS • MEDIUM-DUTY HYDRAULIC APPLICATIONS | • HIGH CREEP STRENTH • HIGH CHEMICAL RESISTANCE • OUTSTANDING WEAR RESISTANCE • ELECTRICAL PROPERTIES LIKE VIRGIN PTFE | • HIPERSEALS • ROTARY SEALS • BACK-UP RINGS |

| PE | 01K | PEEK | BEIGE/ BLACK | -73 | 316 | • HYDRAULIC APPLICATIONS | • GOOD CHEMICAL RESISTANCE • GOOD WEAR RESISTANCE • HIGH MAXIMUM USE TEMPERATURE • LOW FLAMMABILITY • EXCELLENT ELECTRICAL PROPERTIES • GOOD RADIATION RESISTANCE | • BACK-UP RINGS • HIPERSEALS |

| Code | Material | Cantilever Spring | Canted Coil Spring | Helical Spring | Full Contacted Spring |

| 1 | 301 Stainless Steel | Standard | ✓ | Standard | |

| 2 | Hastelloy® C276 | ✓ | ✓ | ✓ | |

| 3 | 17-7 PH Stainless Steel | Standard | |||

| 4 | lnconel® 718 | ✓ | |||

| 5 | Elgiloy® | ✓ | |||

| 6 | 302 Stainless Steel | Standard | |||

| 7 | 304 Stainless Steel | ✓ | |||

| 8 | 316 Stainless Steel | ✓ | ✓ | ✓ |