HiPerLip® - PTFE Rotary Lip Seal with Metal Casing

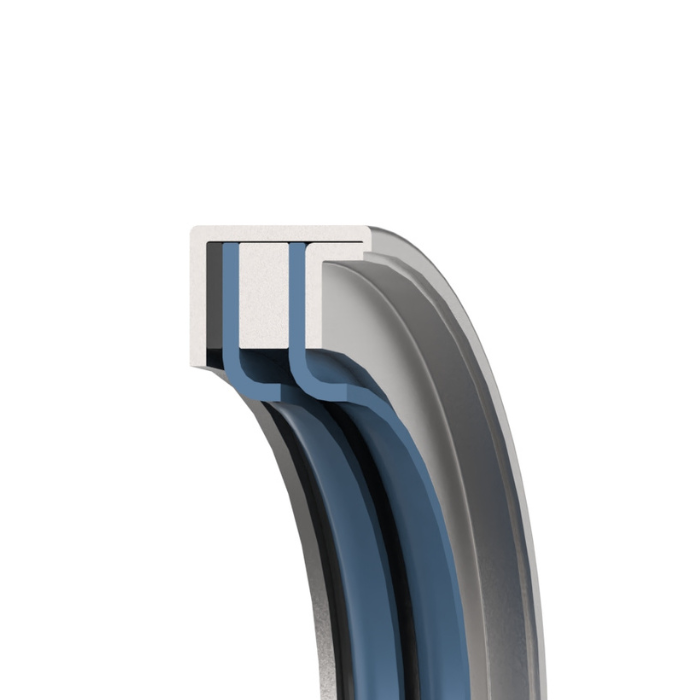

PTFE Rotary Lip Seal | Type K2

Teflon rotary lip seal with dual primary lips.

- Suitable for medium to high speed application

- Suitable for low to medium pressure

- Abrasive-Resistant and pressure-stable, for use in fans, pumps, compressors, gear-boxes, and engine crank case.

- Either clockwise (CW) or counter- clockwise (CCW) threaded PTFE lip can be used to pump lubricating oil away from the seal.

- Low friction can be achieved via hydrodynamic effect on the sealing lip.

Application Range

- Speed: ≤ 18 m/s

- Pressure: ≤ 35 bar

- Temperature: -150°C ~ 225°C

Common Applications

Optional Design

Guidelines for the Selection of Special Sizes

Unit: mm| Shaft diameter | Outside diameter | Casing width |

| 8 | 22 | 7 |

| 8 | 24 | 7 |

| 8 | 26 | 7 |

| 9 | 22 | 7 |

| 9 | 24 | 7 |

| 9 | 26 | 7 |

| 10 | 22 | 7 |

| 10 | 24 | 7 |

| 10 | 26 | 7 |

| 12 | 22 | 7 |

| 12 | 24 | 7 |

| 12 | 26 | 7 |

| 12 | 28 | 7 |

| 12 | 30 | 7 |

| 14 | 24 | 7 |

| 14 | 28 | 7 |

| 14 | 30 | 7 |

| 14 | 35 | 7 |

| 15 | 26 | 7 |

| 15 | 30 | 7 |

| 15 | 32 | 7 |

| 15 | 35 | 7 |

| 16 | 28 | 7 |

| 16 | 30 | 7 |

| 16 | 35 | 7 |

| 17 | 28 | 7 |

| 17 | 30 | 7 |

| 17 | 32 | 7 |

| 17 | 35 | 7 |

| 17 | 40 | 7 |

| 18 | 30 | 7 |

| 18 | 32 | 7 |

| 18 | 35 | 7 |

| 18 | 40 | 7 |

| 20 | 30 | 7 |

| 20 | 32 | 7 |

| 20 | 35 | 7 |

| 20 | 40 | 7 |

| 20 | 47 | 7 |

| 22 | 32 | 7 |

| 22 | 35 | 7 |

| 22 | 40 | 7 |

| 22 | 47 | 7 |

| 24 | 35 | 7 |

| 24 | 37 | 7 |

| 24 | 40 | 7 |

| 24 | 47 | 7 |

| 25 | 35 | 7 |

| 25 | 40 | 7 |

| 25 | 42 | 7 |

| 25 | 47 | 7 |

| 25 | 52 | 7 |

| 26 | 37 | 7 |

| 26 | 42 | 7 |

| 26 | 47 | 7 |

| 28 | 40 | 7 |

| 28 | 47 | 7 |

| 28 | 52 | 7 |

| 30 | 40 | 7 |

| 30 | 42 | 7 |

| 30 | 45 | 7 |

| 30 | 47 | 7 |

| 30 | 50 | 7 |

| 30 | 52 | 7 |

| 32 | 45 | 8 |

| 32 | 47 | 8 |

| 32 | 52 | 8 |

| 35 | 47 | 8 |

| 35 | 50 | 8 |

| 35 | 52 | 8 |

| 35 | 55 | 8 |

| 35 | 62 | 8 |

| 38 | 55 | 8 |

| 38 | 58 | 8 |

| 38 | 62 | 8 |

| 40 | 52 | 8 |

| 40 | 55 | 8 |

| 40 | 60 | 8 |

| 40 | 62 | 8 |

| 42 | 55 | 8 |

| 42 | 60 | 8 |

| 42 | 62 | 8 |

| 42 | 72 | 8 |

| 45 | 60 | 8 |

| 45 | 62 | 8 |

| 45 | 65 | 8 |

| 48 | 65 | 8 |

| 50 | 68 | 8 |

| 50 | 72 | 8 |

| 52 | 72 | 8 |

| 55 | 72 | 8 |

| 55 | 80 | 8 |

| 60 | 75 | 8 |

| 60 | 80 | 8 |

| 60 | 85 | 8 |

| 62 | 80 | 8 |

| 65 | 85 | 8 |

| 65 | 90 | 10 |

| 65 | 100 | 10 |

| 68 | 90 | 10 |

| 68 | 100 | 10 |

| 70 | 90 | 10 |

| 70 | 95 | 10 |

| 70 | 100 | 10 |

| 75 | 95 | 10 |

| 75 | 100 | 10 |

| 80 | 100 | 10 |

| 80 | 110 | 10 |

| 85 | 110 | 10 |

| 85 | 120 | 12 |

| 90 | 110 | 10 |

| 90 | 120 | 12 |

| 95 | 120 | 12 |

| 100 | 120 | 12 |

| 100 | 125 | 12 |

| 100 | 130 | 12 |

| 105 | 130 | 12 |

| 110 | 130 | 12 |

| 110 | 140 | 12 |

| 115 | 140 | 12 |

| 115 | 150 | 12 |

| 120 | 150 | 12 |

| 125 | 150 | 12 |

| 125 | 160 | 12 |

| 130 | 160 | 12 |

| Further sizes on request |

| Material code | Reference | Compound | Color | Temp. °C (MIN.) | Temp. °C (MAX.) | Application | Characteristics | Products |

| 1 | 01T | VIRGIN PTFE | WHITE | -190 | 220 | • CHEMICAL INDUSTRY • SEMI-CONDUCTOR • FOOD INDUSTRY | • HIGH CHEMICAL RESISTANCE • LOW COEFFICIENT OF FRICTION | • BACK-UP RINGS • HIPERSEALS |

| 2 | 03T | PTFE + CARBON + GRAPHITE | BLACK | -190 | 315 | • HIGH MECHANICAL STRESS • WATER/OIL HYDRAULICS • ROTARY SEALING | • HIGH WEAR RESISTANCE • CREEP RESISTANCE | • GLIDE RINGS • PNEUMATIC GUIDANCE TAPE • BACK-UP RINGS • HIPERSEAL |

| 3 | 02T | PTFE + BRONZE | GREEN | -156 | 260 | • HIGH MECHANICAL STRESS • HYDRAULIC APPLICATIONS | • OUTSTANDING WEAR RESISTANCE • EXTRUSION RESISTANCE • CREEP RESISTANCE | • GLIDE RINGS • HYDRAULIC GUIDANCE TAPE • BACK-UP RINGS |

| 4 | UPE | UHMW-PE | WHITE | -200 | 80 | • HYDRAULIC APPLICATIONS | • OUTSTANDING WEAR RESISTANCE • GOOD OXIDATION RESISTANCE • OUTSTANDING EXTRUSION RESISTANCE • OUTSTANDING SEALING UNDER LOW PRESSURE | • BACK-UP RINGS • SPRING ENERGIZED SEALS |

| 4G | 4G | ULTRAGOLD® | YELLOW | CRYOGENIC | 93 | • HYDRAULIC APPLICATIONS | • OUTSTANDING WEAR RESISTANCE • SELF-LUBRICATING PROPERITIES • OUTSTANDING EXTRUSION RESISTANCE • OUTSTANDING PERFORMANCE UNDER CRYOGENIC APPLICATION | • HIPERSEALS |

| 5 | 05T | PTFE + CARBON FIBER | GREY | -260 | 310 | • WATER HYDRAULICS • SHORT STROKES WITH HIGH OPERATION FREQUENCY | • VERY GOOD WEAR RESISTANCE PROPERTIES IN WATER • EXCELLENT COMPRESSIVE STRENGTHS • DYNAMIC APPLICATIONS AT HIGH SPEED | • GLIDE RINGS • HIPERSEALS |

| 6 | 06T | PTFE + GLASS FIBER | WHITE | -190 | 290 | • MEDIUM-DUTY HYDRAULIC APPLICATIONS | • HIGH CHEMICAL RESISTANCE • HIGH CREEP RESISTANCE • ELECTRICAL PROPERTIE LIKE VIRGIN PTFE | • GLIDE RINGS • BACK-UP RINGS • GUIDE RINGS • GASKETS |

| 7 | 07T | PTFE + EKONOL | BEIGE | -260 | 320 | • MEDIUM MECHANICAL STRESS • SOFTER SEALING SURFACES • ROTARY SEALING | • LIMITED CHEMICAL RESISTANCE • LIMITED USE IN HOT WATER | • HIPERSEALS • ROTARY GLIDE RINGS • LIP SEALS |

| 8 | 08T | PTFE + E-CARBON | BLACK | -190 | 290 | • MEDIUM MECHANICAL STRESS • HARD SEALING SURFACES • WATER/OIL EMULSIONS | • CHEMICAL RESISTANCE LIMITED BY CARBON | • HIPERSEALS |

| 9 | 09T | PTFE + GRAPHITE | DARK GREY | -190 | 260 | • LOW MECHANICAL STRESS • SOFT SEALING SURFACES | • CHEMICAL RESISTANCE LIMITED GRAPHITE | • HIPERSEALS |

| 10 | 10T | PTFE + GLASS FIBER + MOS2 | GREY | -190 | 260 | • MEDIUM MECHANICAL STRESS • MEDIUM-DUTY HYDRAULIC APPLICATIONS | • HIGH CREEP STRENTH • HIGH CHEMICAL RESISTANCE • OUTSTANDING WEAR RESISTANCE • ELECTRICAL PROPERTIES LIKE VIRGIN PTFE | • HIPERSEALS • ROTARY SEALS • BACK-UP RINGS |

| PE | 01K | PEEK | BEIGE/ BLACK | -73 | 316 | • HYDRAULIC APPLICATIONS | • GOOD CHEMICAL RESISTANCE • GOOD WEAR RESISTANCE • HIGH MAXIMUM USE TEMPERATURE • LOW FLAMMABILITY • EXCELLENT ELECTRICAL PROPERTIES • GOOD RADIATION RESISTANCE | • BACK-UP RINGS • HIPERSEALS |

| Code | Material | Application |

| METAL CASING | ||

| 1 | Carbon steel | Low cost Standard material for metal case General application without corrosion issue |

| 2 | Stainless steel 304 | General application under corrosive environment |

| 3 | Stainless steel 316 | General application for corrosive media |

| GASKET | ||

| 1 | NBR | Standard material for temperature range from -40 to 100℃ |

| 2 | FPM(Viton®) | Chemical and heat resistant material Temperature range from -20°C to 200°C |